Our Technology and Solution

TECHNOLOGY AND PRODUCT DESCRIPTION

Briquette charcoal is a specialized form of charcoals made by compressing sawdust and other wood products without additives. The raw material is solely sawdust, produced from various species of tropical wood , eg. Odum, )donawoma, )fram, Essa, Wawa etc.

The moisture content of this fresh of raw sawdust varies from about 40-70%. The raw or fresh sawdust is first screened to remove contaminants and oversized particles. They are them dried to a moisture content of about 8-10% in an impulse dryer with hot air that is generated using wood wastes. The fairly dry sawdust is then fed into a screw type briquettes machine (extruder) for compaction into briquettes.

The density of the briquettes formed is around 1200kg/m. The briquettes that leaves the briquetting machine (extruder) are hot and slightly roasted on the outside. These hot and slightly roasted briquette are left in the open to cool. The cooling process further enhances the binging between the sawdust particles.

The sawdust briquettes are the neatly arranged in a kiln /oven with air flow homes at the lower portion. The loaded briquettes inside the kiln are then sealed. The carbonization process is started by putting a few pieces of lighted briquettes on top of the pile through a hole into the kiln.

Carbonization (or partial pyrolysis) drives off volatile compounds to leave more or less pure carbon; the biomass is heated to within a critical temperature band (around 300 degrees Celcius) but with a restricted supply of air so it does not ignite. The sawdust briquettes are carbonized at a temperature of 850-875 degrees for 3 days (108 hours) with air flow that is controlled a various stages of the process.

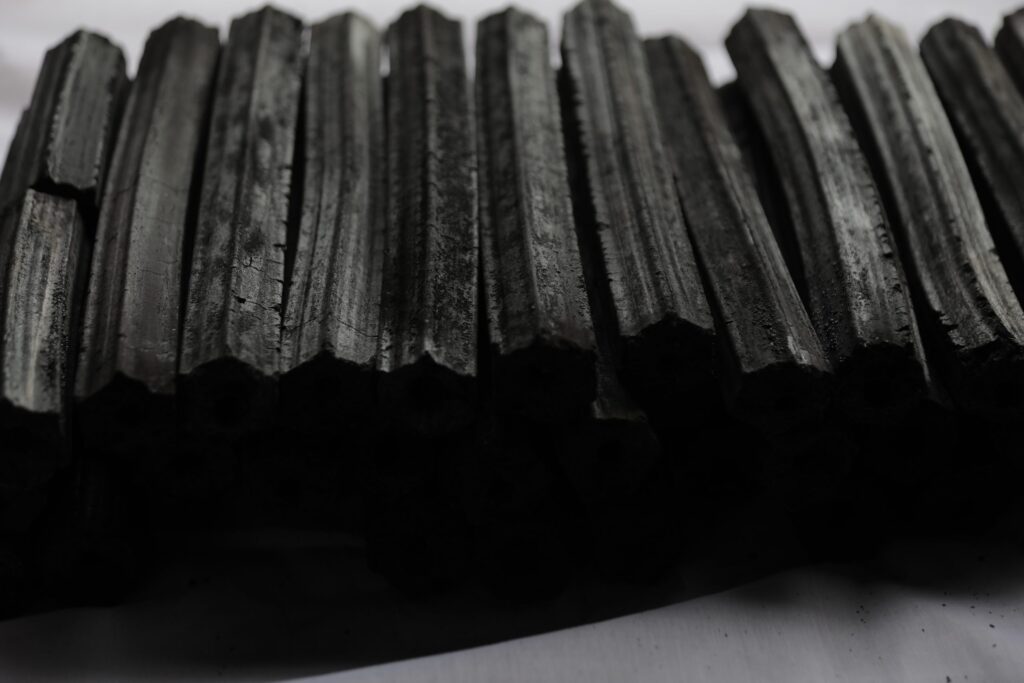

A good control of the air-flow is essential in ensuring that good quality charcoal are produced. On top of the kilns or oven are manufracted pipes that channel the smoke the then collected into coal. When the carbonation process is completed which is indicated by emission from the chimneys becoming invisible, the briquettes are allowed to cool and packaged into boxes.

DESCRIPTION ON TENCHNOLOGY OF SAW DUST CHARCOAL BRIQUETIES

- First pass the Saw Dust into a crusher to crush them into about 5mm size.

- Then pass the crushed materials through a sever to eliminate any foreign materials, then through a large drum dryer to reduce its moisture content, it should be dried to a moisture content of between 8 – 12 percent.

- Once you have the material dried, feed the saw dust into biomass Briquettes Machines by pressing it inside the machine

- Compress the Biomass Briquettes Machines under high pressure and temperature in a process known as Briquetting.

- During this process there, is self-bonding which involves thermoplastic flow of the Biomass.

- Lignin Content in formed naturally inside the Biomass machine due to high pressure and temperature, and it is liberated. It serves as glue, binding and compressing the Biomass to form high density Briquettes.

- Whiles inside the screw Briquette machine, the materials being Briquetted are stirred by a center shaft inside the machine to ensure a uniform combustion.

- Once the Biomass has been Briquetted, they are placed into carbonization furnace. The carbonization period is between 3-4 days, after which the carbonized Briquettes should be taken out from carbonized furnace for cooling. The cooling period is also between 3-4 days.

- After the above process the final carbonized Briquettes is said to be ready for boxing, scaling and double strip before kept in the warehouse awaiting for export.

- Moreover, just like the natural charcoal, it will be smokeless and odor free. The charcoal Briquettes is an environmental friendly product because it does not pollute the environment.